The last chapter of the ritual Classic Zhouli, the Kaogongji 考工記, is an account of offices concerned with the production of objects needed by the imperial household. The work encompassed woodcarving, metalwork, processing of animal skins, the production and application of colours, engraving and polishing, and pottery. Even if the chapter found its transmitted shape as late as during the Warring States period, it gives insight into the manifold crafts used by the royal court and those of the regional rulers in the early Zhou. Archaeology added to our knowledge about Western Zhou handicrafts. Functionaries of the Zhou court supervised the "hundred workers" (baigong 百工), among which also women were found (Zhou 2000: 821).

In the early Western Zhou, war captives were entrusted with manufactural work. Craftsmen of the Shang were resettled to the Zhou capitals and took over work for their new masters. Tombs found in Luoyang show that Shang craftsmen were not only highly regarded for their expertise, but also retained their own customs and habits over generations. Inheritance of positions were common among craftsmen as it was among the nobility. Instruction was only carried out orally.

The relatively peaceful age of the Western Zhou period as well as the specific patronage of arts and crafts contributed to progress in techniques. The spread of crafted products throughout the country is related to a specialization of some groups of Shang people in commerce (see Shang economy).

The most famous crafted products of the Western Zhou period are the bronze vessels used for ancestral sacrifices, during banquets, and as carriers of documents like investitures of regional rulers and other members of the nobility. Finally, the so-called "ritual revolution" in the mid-Western Zhou period utilized sets of bronze vessels (lieding 列鼎) to express the rank of a dignitary. The production of bronze vessels required higher skills than other products like weapons or metal components of chariots.

xxx Images of ding, gui, weapon, bell |

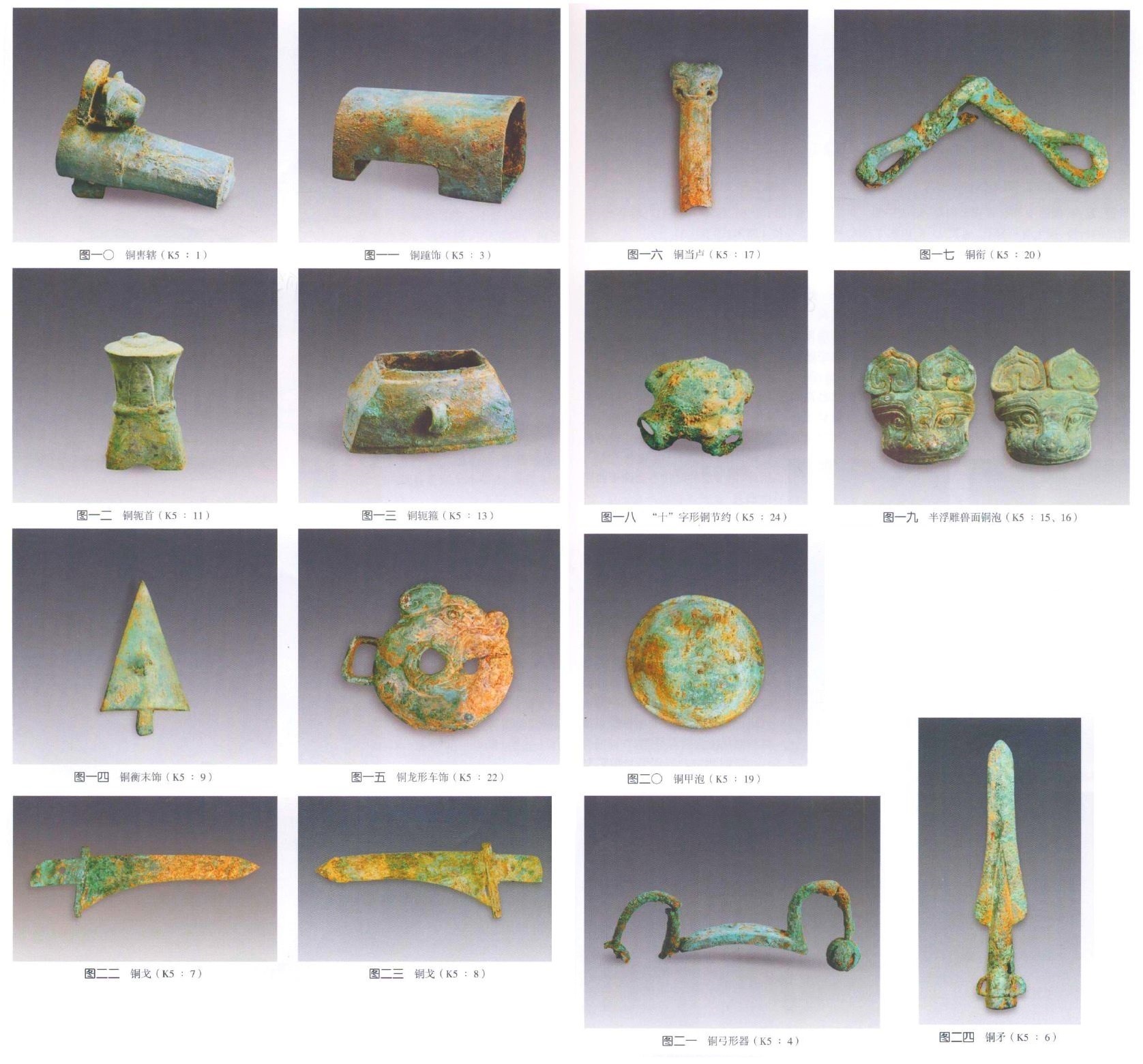

Metal parts of a chariot unearthed in Beiyao 北窯 near Luoyang, Henan. First row: axle-cap (wei 軎) with linchpin (xia 轄), "shoe" (zhong 踵), browband decoration (danglu 當盧), snaffle bit (xian 銜); second row: yoke end (e 軛), yoke fastener (egu 軛箍), cross-shaped linking part (jieyue 節約), bosses in the shape of animal heads (shoumian tongpao 獸面銅泡): third row: arrowhead-shaped decoration, dragon-shaped decoration of the bridles, round boss: last row: two dagger-axes (ge 戈), bow fitting, and spearhead. From Liu et al. 2011. |

|

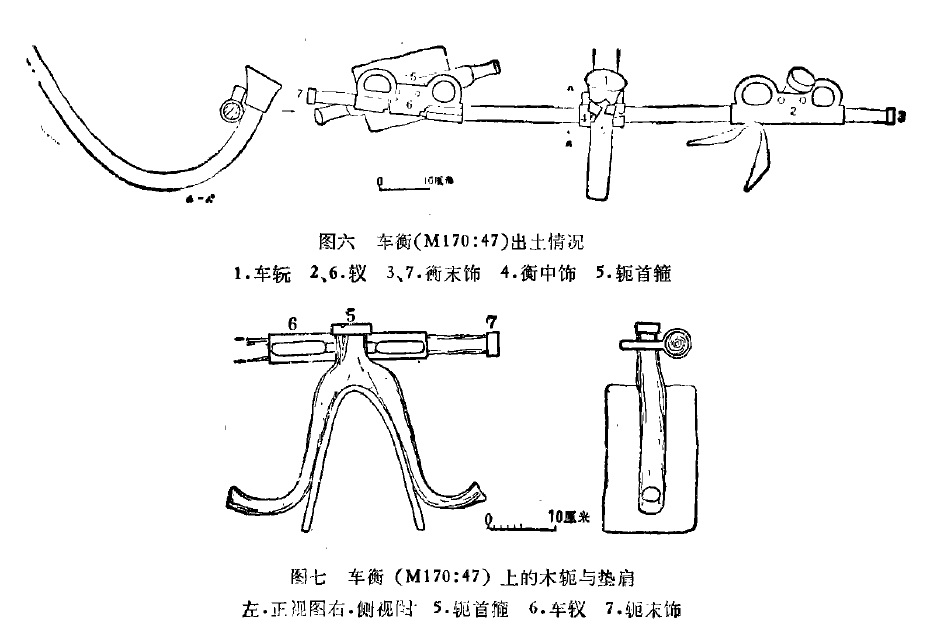

Metal parts of a yoke, reconstruction, found in the tomb of the Elder of Xing (Xing Shu 井叔) unearthed in Zhangjiapo 張家坡 near Xi'an, Shaanxi. From Zheng 1990. |

In the early Western Zhou, the royal court had still a monopoly over the possession and processing of bronze. When presenting a dignitary with bronze, the royal workshop was responsible for the transformation of the metal into a precious vessel. Yet in the course of time, most of the regional states founded their own workshops which mastered the creation of ritual vessels. In Luoyang and the Western twin capitals Feng-Hao, archaeologists discovered workshops with furnaces, models, and scrap metal. Remains of furnaces were found in Beiyao 北窯 close to the eastern capital Luoyang, and even in the places of some smaller states in the west like Yu 𢐗 or Ying 應, Deng 鄧, or Shen 申 in Henan.

Most cooking vessels (ding 鼎, li 鬲, yan 甗, gui 簋/𣪕), drinking vessels (jue 爵, gu 觚, jiao 角), and serving vessels (hu 壺, you 卣, zun 尊, zhi 觶, lei 罍, he 盉, fangyi 方彝) were inherited from the Shang, but the Zhou reduced the number of wine vessels and introduced some new forms. The traditional decorations of taotie masks, birds, dragons (kui), snakes, cicadas, and geometrical patterns were likewise adopted from earlier forms, but the number of taotie shrank, and gave prevalence to more geometrical patterns (clouds, waves, whirls, leaves, rhombuses, nipples). Inscriptions became much longer, making bronze vessels important carriers of documents.

Not thoroughly new was the use of bells, but the amount of musical instruments drastically increased during the Western Zhou, not only in absolute numbers, but also in the size of sets of 'carillons' enjoyed during ceremonies and banquets. In the late Western Zhou period, decoraions became more decent, vessels more crude, but cast with higher skills and in a more standardized way. At the same time, the custom of funerary vessels (mingqi 明器) appeared which were specifically produced for use as burial objects, and therefore of minor quality. The forming and casting techniques were used as invented and developed by the Shang craftsmen.

The alloy of the bronze or brass objects (usually just called 'bronze') was not standardized. Analysis shows that there were high-tin (more than 10%), high-lead (more than 10%), and tin-lead (both metals at least 10%) products among the 'bronze' vessels (Zhou 2000: 841). The alloy seems to have depended on the availability of the secondary metals. Inscriptions prove that bronze was quite a precious item and served as present by the king. It was also hoarded, as can be seen in a tomb find from Gouyuan 溝原 near Fufeng 扶風, Shaanxi (Zhou 2000: 842). Bronze tools usually had high tin and lead contents, which corresponds to a statement in the Zhouli where the six levellings of copper and tin (liuqi 六齊) are described.

| six alloys (liuqi 六齊) | copper, bronze 金(=銅), or whole amount of metal | tin 錫 | |

|---|---|---|---|

| 鍾(=鐘)鼎之齊 | bells and tripods | 6 parts | 1 part (14.3%) |

| 斧斤之齊 | axes | 5 | 1 (16.7%) |

| 戈戟之齊 | dagger-axes and 'halberds' | 4 | 1 (20%) |

| 大刃之齊 | swords | 3 | 1 (25%) |

| 削殺矢之齊 | arrowheads | 5 | 2 (28.6%) |

| 鑒燧之齊 | mirrors | 1 | ½-1 (33.3-50%) |

Source: Zhouli 周禮, part Kaogongji 考工記, ch. Zhouren 輈人. |

|||

Apart from the basic problem of interpreting the word jin 金 (as bronze, or as pure copper), there is a semantic problem, leading to question whether the sentence X分其金而錫居其一 means "tin makes out one part out of X parts of the metal (as a whole)", or "add one part of tin to X parts of copper/bronze" (interpretation in the table) (Zhao & Zhou 1998: 131).

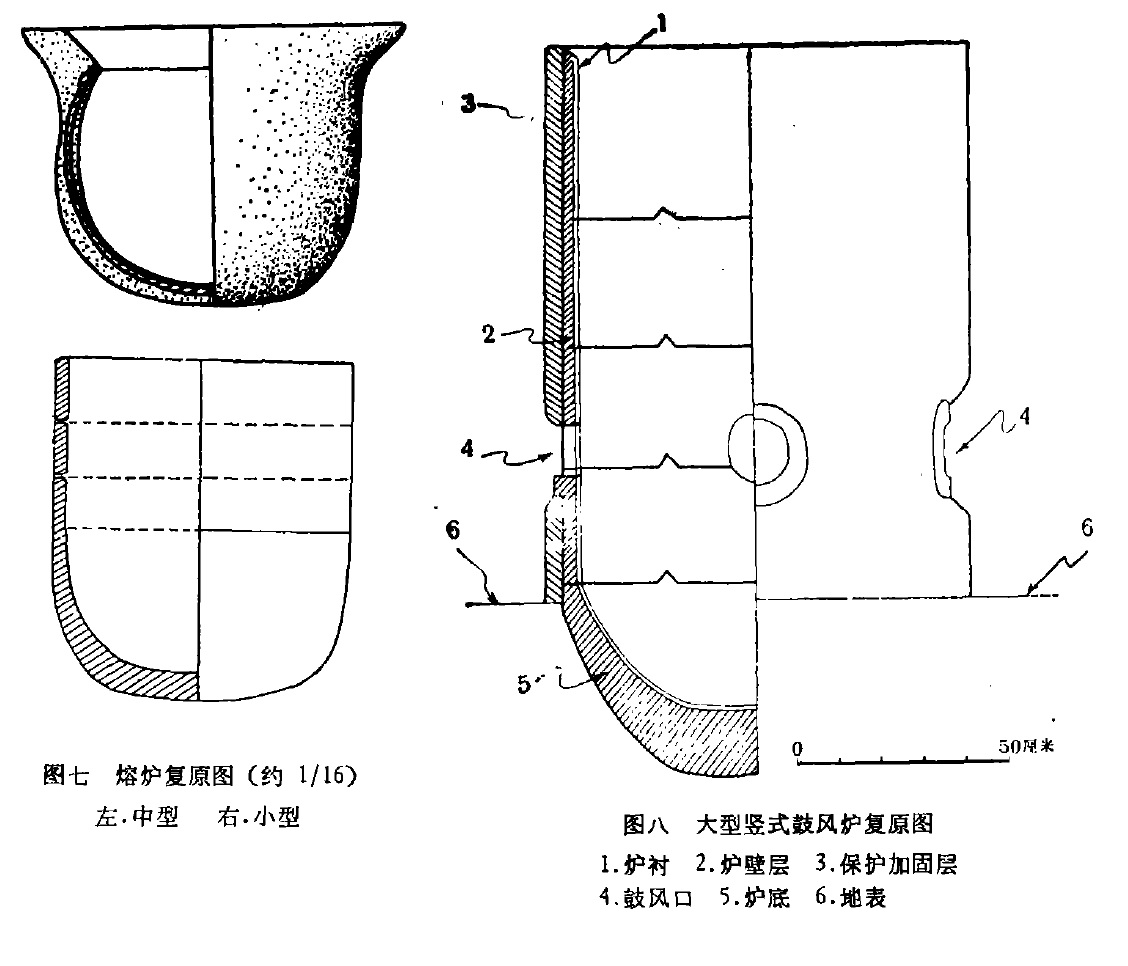

The workshops of Beiyao in Luoyang included three types of smelters, namely two smaller types and a larger one. The small crucible (ganguo 坩堝) had a round bottom and were made of loam. The inner surface was clad with furnace lining (luchen 爐襯) of fine loam (xini 細泥), and the outside wall consisted of loam mixed with straw (caobanni 草拌泥). The mid-size crucible was less round, and the 'shaft' consisted of several rings fitting together by a mortise-and-tenon system (sunmao 榫卯). The lower part of the large crucible was standing in the earth and was not round, but rather formed with inclined angles. The shaft consisted of four rings with a diameter of 80 cm and handles. The wall of this fix crucible consisted of three parts and had four openings for bellows (gufengkou 鼓風口). Bellows (tuo 橐) were made of cowhides or sheepskins. The use of four bellows allowed to raise the temperature inside the crucible up to 1,250°C (Ye 1984: 662).

|

Reconstructions of three types of crucibles found in Beiyao near Luoyang, Henan. The ring construction of the mid-size and the large crucible can be seen. The large crucible has openings for bellows on each side. The crucibles were charged with charcoal and the metals, yet it remains unclear how the molten metals were poured into the moulds. Below the right crucible is a scale of 50 cm. From Ye 1984. |

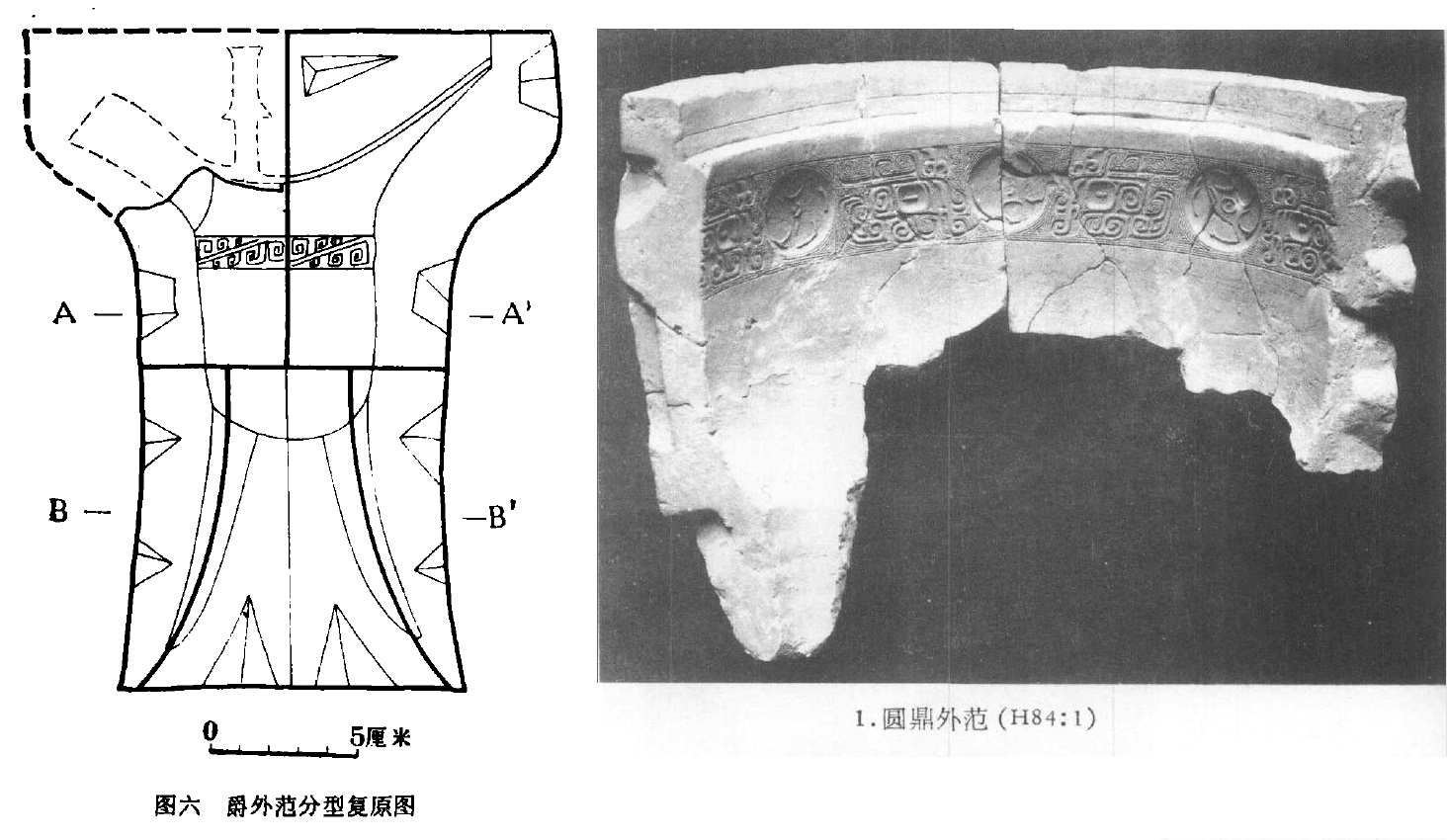

Metal objects were cast with the help of moulds. Depending on the complexity of the object, moulds consisted of several parts. The remains of the workshops in Beiyao show not just fragments of moulds, but also various steps in the production of moulds, beginning with the preparation of the main substance, fine loam mixed with ash and shell powder, the forming and decoration of models (nimo 泥模), the production of inner and outer moulds (the inner being more fine than the outer material), and the refinement of the objects (fettling and polishing) when the casting process was done. Even then, ridges remained on the vessels which allow to reconstruct the assembling of the moulds.

|

The left image shows a reconstruction of moulds for a jue 爵-type beaker. It can be seen how complex the composition of moulds was even for a small object (c. 18 cm height) like a three-footed beaker. The right image shows the fragment of an outer mould for a ding 鼎 tripod. From Ye 1984, and Ye & Zhang 1983, Plate 5. |

Mines from the Western Zhou period have not been discovered so far. The chapter Yugong 禹貢 of the Shangshu reports that metals were presented as tributes in the provinces of Jingzhou 荊州 and Yangzhou 揚州 (middle and lower Yangtze regions), which corresponds to Shang-period mining sites in Ruichang 瑞昌, Jiangxi, or Piling 毗陵 near Yangxin 陽新, Hubei. Some of them were opened during the Shang period or even before, and were in operation until the Spring and Autumn period. The mine of Tonglüshan 銅綠山, Hubei, yielded a substantial amount of ores over centuries, and the mines of Dagongshan 大工山 near Nanling 南陵, Anhui, were in operation until the Tang period 唐 (618-907).

|

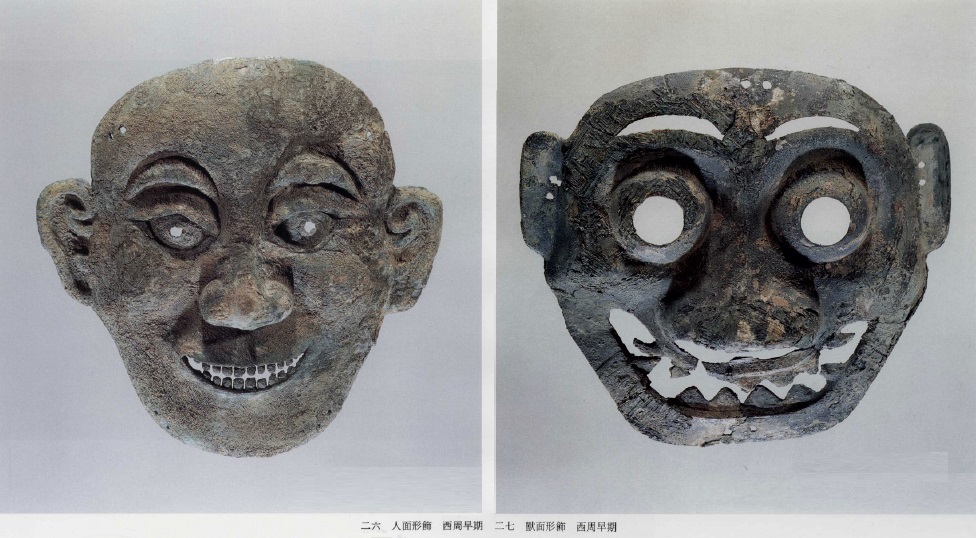

Bronze masks unearthed in 1968 in Liulihe close to Beijing, regional state of Yan, early Western Zhou. Heigth 17.6 and 22.3 cm, respectively. From Zhonggu Qingtongqi 1991, Vol. 2, nos. 26-27. |

The control of mines was an important matter, and the Zhou court therefore sent the Duke of Shao 召公 to inspect the sites, and created a series of small states (reigned by kinsmen of the royal house) between the Yellow River Plain and the Yangtze Region which served as garrisons for the control of the copper ore traffic to the north (jindao xixing 金道錫行 "copper routes and tin roads"; Zhou 2000: 855). The same is true for the regional state of Wu which was reigned by a kinsmen of the royal family Ji 姬. The southern campaign of King Zhou might have had the control of the copper routes as a background.

Apart from trade, copper ores were delivered to the royal house in the shape of tributes, as can be seen in the inscription of the cover of the Gong Ao gui 𡱒敖𣪘 (Jicheng 4213) pot, which speaks of a huge copper/bronze tribute to the Zhou king.

Even if shape and technique of objects of daily use did not greatly change in comparison to the Shang period, the Western Zhou period saw the invention of tiles and the advancement of firing techniques for proto-porcelain. A third novelty was the concept of 'objects for the dead' (mingqi 明器) for use in the "dark" world (youming 幽冥), namely bronze and pottery objects particularly produced for burials, made with a symbolic value, and therefore of minor quality by contrast with 'objects for the living'.

There was pottery for cooking—mostly with three legs—, dinnerware, and the omnipresent pottery for storage, some of them huge jars (guan 罐, weng 甕 or 瓮, pou 瓿 or bu 䍌), but also jugs (hu 壺), and basins (pen 盆). The royal household and those of the regional rulers employed potters (taoshi 陶氏), but there must likewise have been potters producing objects for the common people. Among such objects, an ocarina was found (Fang 2008).

|

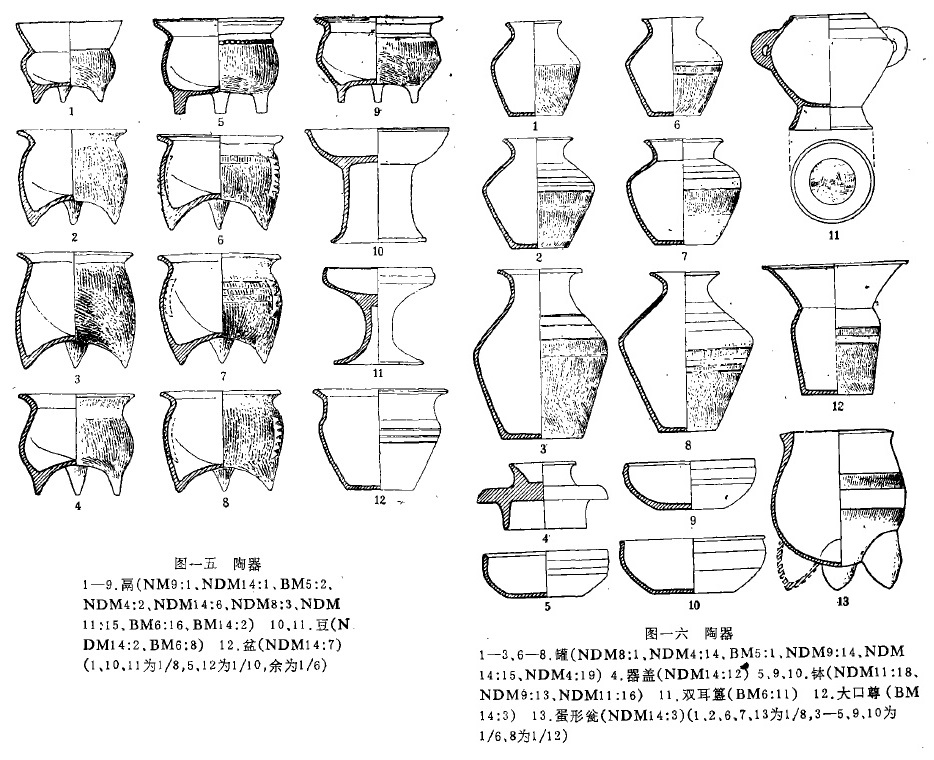

Li 鬲 tripods (1-9), dou 豆 beakers (10-11), and pen 盆 jar (12, left); guan 罐 jars (13-,6-8), cover (4), bo 缽 bowls (5, 9-10), gui 簋 vessel (11), zun 尊 pot (12), weng 甕 tripod (13, right). From Zhang et al. 1987. |

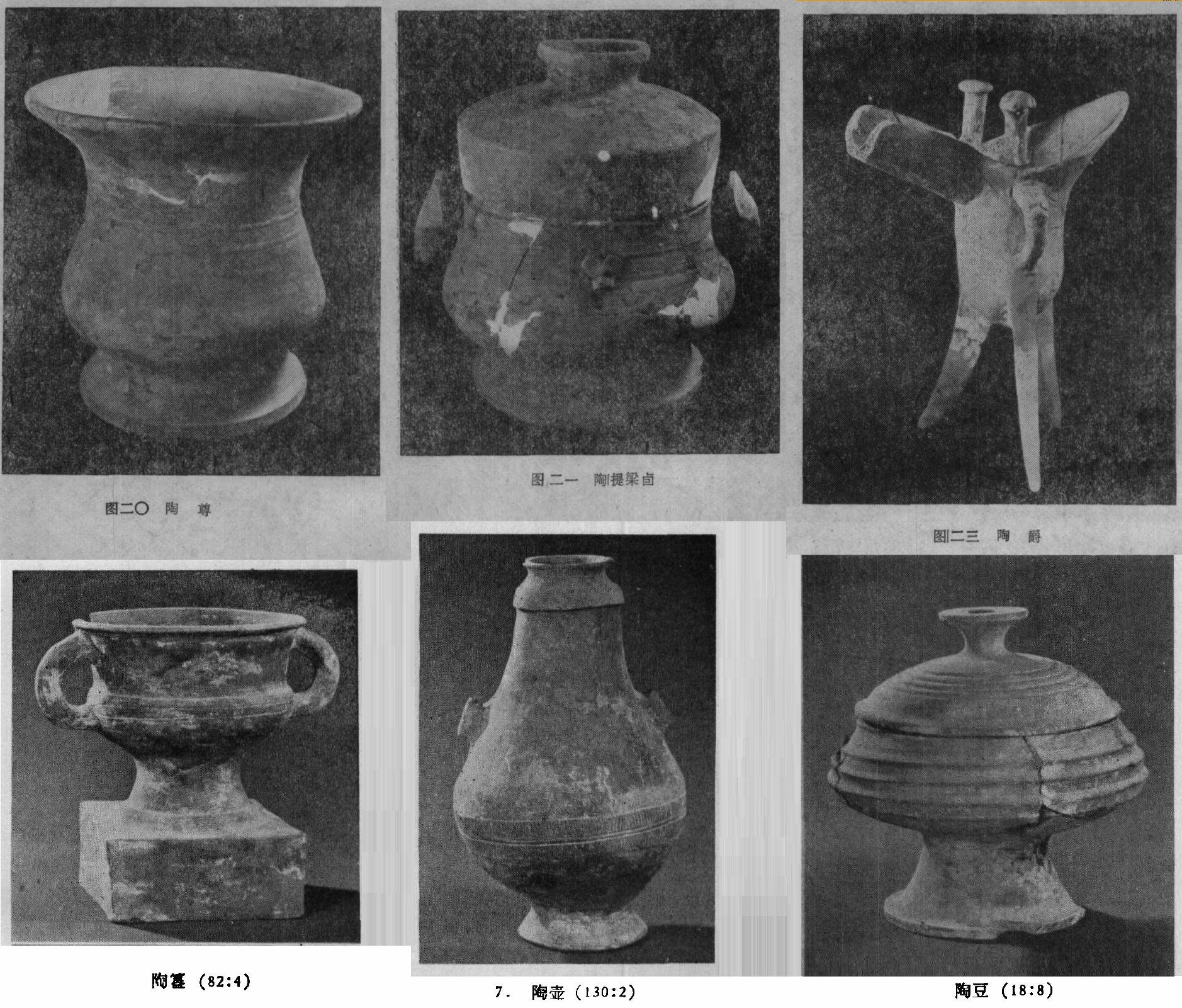

Tiles were found not only in the royal residences in the west, like in Zhangjiapo 張家坡 near Xi'an, Shaanxi, but also in the workshops of Qufu, Shandong, the capital of the regional state of Lu. In all workshops discovered so far potter's wheels had been used (taojun 陶均, taolun 陶輪), yet there were a number of vessels for which the use of a wheel was not possible, particularly the three-legged li 鬲 pots with their "bag-feet" (daizu 袋足), or the yan 甗 steamer which was a combination of a li and a grid-bottom zeng 甑 pot on the top. While the early bronze vessels of the Shang period had been imitations of pottery, the trend during the Western Zhou was reverse, making the day-to-day dinnerware imitations of the precious bronze objects, like ceramic gui 簋, you 卣, he 盉, or jue 爵. Such 'cheap' ware was particularly used for burials (Zhou 2000: 860).

|

Various types of pottery made as imitations of bronze vessels. Top: zun 尊, you 卣, he 爵; bottom: gui 簋, hu 壺, dou 豆. From Zhongguo Shehui 1980, Plates 9-10; Shaanxi Zhouyuan 1979, fig. 20-21, 23. |

Pots were decorated with stripes, curves, bows, scales, clouds, whirls, triangles, S-shapes, etc. before firing. For decorative purposes, potters used decoration markers (taopai 陶拍) and pottery chops (tao yachui 陶壓錘) (Li at al. 1990). In the western region, the pre-dynastic Zhou style continued for long, while Shang-style shapes and decorations dominated in the east, due to the fact that former Shang artisans were employed in Chengzhou (Luoyang) and some eastern garrisons (Zhou 2000: 863).

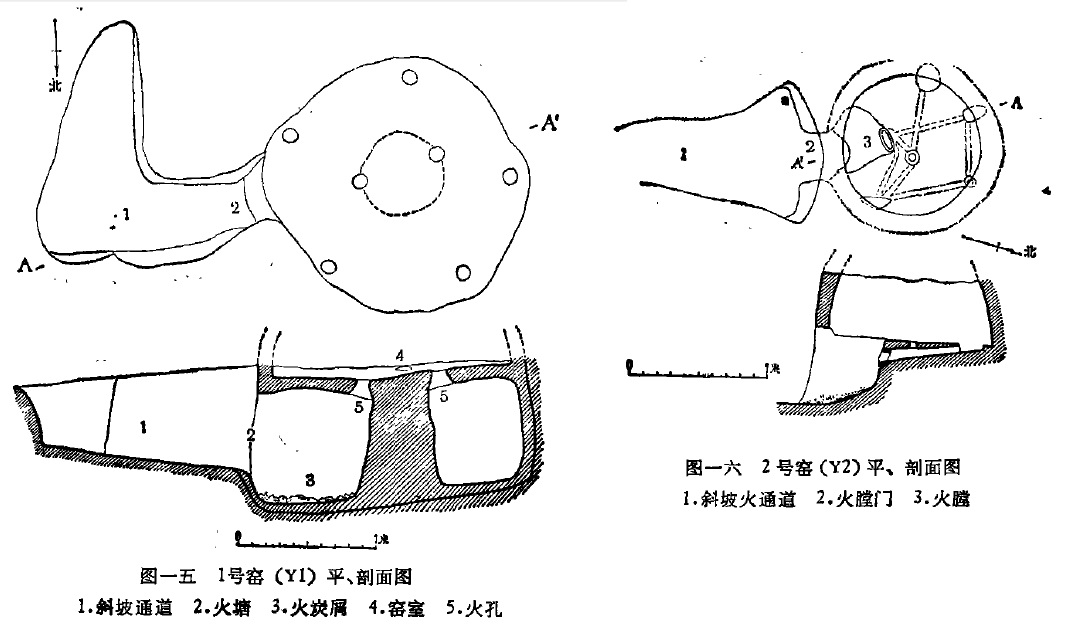

In the early Western Zhou period, the traditional rising-blaze kiln (zhiyanyao 直焰窯) was still used in which the blaze went through a grid on which the shards (taopi 陶坯, pitai 坯胎) were standing. Later on, a kiln became widespread in which the heat was led from the firing chamber into a "horizontal" (yet inclined) chamber where the shards were fired. This type of horizontal-blaze furnace (hengyanyao 橫焰窯) allowed to make use of different grades of heat, with highly-fired objects standing closer to the fire and objects fired with lower temperatures more distant. Fragments of pottery show that the quality rose in the course of the Western Zhou period, from many "red earthenware" (hongtao 紅陶) with stains to the finer "gray earthenware" (huitao 灰陶) baked with a regular colour.

|

Remains of kilns from the western metropolitan region of Feng-Hao near Xi'an, Shaanxi. From Dai 1986. |

Southeast China had been leading in the invention of hard-fired pottery. This technique became more widespread in the early Zhou empire. It is characterized by shards decorated with geometrical patterns and fired at high temperature (1,100°C). The clay used for this type of pottery was not kaolin, but an iron-rich clay called "purple-gold earth" (zijintu 紫金土) used for the modern pottery from Yixing 宜興, Jiangsu. The combination of this type of earth and firing temperature resulted in a smooth shimmering on the surface of the fired objects which resembles a glaze, and a hard structure giving the object a bell-like sound when knocked—in spite of the relative thickness of the wall. Yet the technique was difficult to standardize, for which reason the colours of high-fired earthenware are not regular, and ranged from dark gray to brown or even "purple" (reddish-brown).

The use of proto-porcelain (yuanshi ci 原始瓷) became widespread though all states, and specimen were found all over Zhou China. Such ware was fired in kilns that can be seen as precursors of the "dragon kilns" (longyao 龍窯) or "dumpling kiln" (mantou yao 饅頭窯) (Li et al. 1990).

The technique of silk production was known during the Shang period, and was refined during the Zhou. The raising of silkworms is described in the Shijing air Qiyue 七月 (part Binfeng 豳風). Also in southeast China, silk textiles were produced and constituted part of the tributes delivered to the Zhou court (Zhou 2000: 911), as can be seen in the chapter Yugong, where it is said that silks and cowries came from the region of Yangzhou 揚州.

The common word for silken cloth was bo 帛, often abbreviated to 白. Tribute silk was stored in the royal vaults, from where "bundles of silk" (boshu 帛束, sishu 絲束) were presented by the king to functionaries. Silk bundles were used as a kind of currency with which, for instance, labour force could be bought (Zhou 2000: 911).

The royal workshops quite probably processed silk yarn or textiles and produced 'brocades', embroidered or figured cloth (jin 錦), a word first mentioned in the lesser ode Xiangbo 巷伯. Fragments or traces of brocade were found in tombs of Baoji and Qishan, Shaanxi. From these artifacts it can be seen that the process of reeling (saosi 繅絲) and degumming (tuojiao 脫膠) was already standard. It is described in the section Huangshi of the Zhouli chapter Kaogongji.

A piece of cloth unearthed in Baoji, Shaanxi, was weaved in twill weave mode (xiewen 斜紋), with rhombic patterns, a technique much more advanced than any Shang-period fabric found to day. The creation of brocade-like fabric requires flat looms instead of the older, inclined or vertical looms. Horizontally arranged loom allow better handling of the shuttle (suo 梭) and winding up the finished part of the product on the warp beam (zhou 軸). It is quite probably that two persons worked together for complex patterns, the one moving the rods (ganggan 杠杆, tizong 提綜) to open a shed in the warps (jing 經, in old texts also written 巠), and the other sending the shuttle throught it to create the wefts (wei 緯) (Zhou 2000: 914-915).

Apart from embroidery (cixiu 刺繡), dyeing cloth or yarn was the most important form of decoration. Cloth or yarn had to be boiled and exposed to the sun in spring (baolian 暴練) before being dyed in summer (with the colours dark red and dark blue, xunxuan 纁玄), and in autumn (with the five colours of the summer pheasant), and being presented to the king in winter, as described in the Zhouli (part Tianguan, ch. Ranren 染人). Red and black colours were created by several repeated dyeings, with different designations for each round, namely base (yuan 源), deep red (cheng 赬), reddish-black (xun 纁), purplish (zou 緅), and black (zi 緇). Nearly all colours are mentioned in inscriptions and transmitted texts, but black, red, yellow, and brown were used most.

Dark-coloured silk robes (xuangun 玄袞) were decorated with embroidery of dragon patterns (longwen 龍紋). Patterns at seams were called fu 黼 or fuchun 黼純, cloud or whirl patterns or multi-coloured figures (juanwen 卷紋) were called zutun {黹+且}屯. Traces of embroidered cloth were found in a tomb in Luoyang, but the oldest real example of embroidery was found in a tomb in Rujiazhuang 茹家莊 near Baoji.

Spindle whorls (fanglun 紡輪) made of ceramics were round, coniform, or had the shape of a frustrum or an abacus. They were used for the production of linen yarn. Linen cloth was woven at a density of 6 to 6, or even 13 strands per cm. The quality of the cloth was important for linen was used in different types for funeral cloth. The unit of 'grammage' was sheng 升, corresponding to 80 strands (lü 縷). Kong Yingda explained that Zhou-period court robes (chaofu 朝服) had a 'grammage' of 15 sheng (for a width of 45 cm), mourning clothes of the zhancui 斬衰 type 3, and those of the qicui 齊衰 type 4 sheng. The finest linen cloth might have had up to 25 or even 50 strands per cm (Zhou 2000: 917-918). For the production process, the fibres of various types of hemp (dama 大麻, zhuma 苧麻, ge 葛, jiancao 菅草, Themeda triandra) were macerated, broken, and then degummed.

The delivery of skins and wool belonged to the duties of local tributes delivered to the royal court. The Zhouli (part Tianguan, ch. Zhangpi) explains that skins (pi 皮, or raw skins, wei 韋) were collected in autumn, tanned leather (ge 革) in winter, and both were delivered to the court in spring. The royal workshop then produced felt (zhan 氈), furs (qiu 裘), and woolen cloth. The production of furs and leatherware was supervised by the siqiu.

Furs of foxen and lambs were often-seen presents of the king to high dignitaries. Leather was used for daily tools like xxx, but also for armour like helms or breastshields. Leather was also used for caps and girdles or similar implements pending from the belt—leather 'aprons' (fu 芾, bi 韠, fu 韍).

李也贞 et al. (1976). “Youguan Xizhou sizhi he cixiu de zhongyao faxian 有关西周丝织和刺绣的重要发现”, Wenwu 文物 1976/2: 60-63.Bones were a very important material for the production of everyday tools like needles (zhen 針), awls, drills (zhui 錐), hairpins (ji 笄), arrowheads (chuo 鏃), and even for agrarian tools or instruments like saws, and were therefore found in great numbers all over the Western Zhou world. The remains of the workshop in Yuntang 雲塘 near Fufeng, Shaanxi, for instance, included no less than 20,000 pieces of discarded bone pieces.

Apart from bone, the workshops also processed horn (jiao 角), ivory (ya 牙), stones, and freshwater shells (bang 蚌). Hairpins were of special interest because they served as adornments and were therefore decorated. The 'heads' of some hairpins had the shape of birds, dragons (kui 夔) or of human beings (Yin 1987).

Jades were seen as precious objects, and the processing of nephrite and similar stones was therefore the business of specialized craftsmen who cut, carved, and polished the pieces. Jades not only counted among the "six auspicious jades" (liurui 六瑞), but also served as presents and gifts given by the king to his dignitaries and the regional rulers, or by the latter to their functionaries. The type of jade or the number of pieces might express the status of its owner. During court audiences, jades were visibly displayed for this reason. Bronze inscriptions speak of court jades as presents (jinzhang 瑾璋). Jades might also be used as tributes of lower-ranked persons to the Zhou king. Jades were often produced in symmetrical pairs, for which a particular numeral word existed, namely jue 玨 or 珏 (Sun 2000).

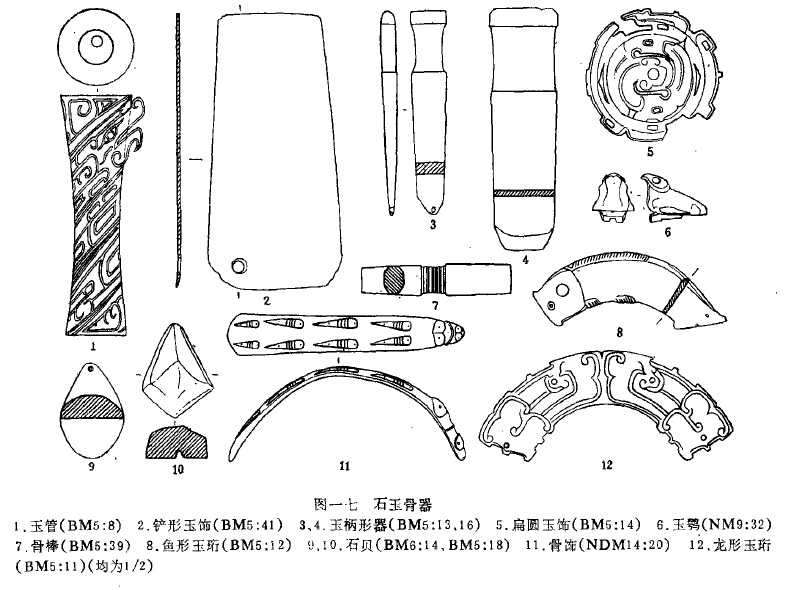

|

xxx. From Zhang et al. 1987. |

There were different types of stones known as 'jade', namely soft jade (ruanyu 軟玉, genuine nephrite), Xiu Jade 岫玉 (local name; also called

Not just nephrite stones, but also other objects, like freshwater shells, ivory, or tortoise shells, originate in places far away from the political and economic centres of the Zhou empire. Apart from ritual objects, jades or similar stones served to produce adornments like beads, necklaces, rings, and the like, and were therefore beautifully adorned by carvings. This also applies to the ritual jades which were decorated with cloud patterns or other geometrical designs. As adornments or art objects, jades were carved into figurines of animals (fishes, birds, tortoises, cicadas) or human beings. Jade was also processed to tools like axes, spaces, adzes (ben 錛), chisels (zao 鑿), or knives (dao 刀, bi 匕), or to ritual objects not belonging to the "six auspicious jades", mainly dagger-axes (ge 戈), of which a large number had survived. The stability of jade weapons for practical use is under discussion. The longest jade dagger is the Taibao yu ge 太保玉戈 with a length of 66.5 cm (Fang 2006, Sheng 2014).

Like bronze vessels or pottery, some jade objects were specifically produced as burial objects. In this function, the tombs of Houma, capital of the regional state of Jin, and of the statelet of Guo, included lavish tomb furnishings of jade objects worked to pendants, necklaces, or jades shaped like eyes or a mouth to be put on the face of the dead. In some objects, jade carries inlays of turquois (Zhou 2000: 886).

Lacquer was a universal material to cover wooden objects, both to protect the base material from decay, and to apply colour. The most important colour were powder of cinnabar or soot. Even if the most famous lacquered objects date from the Warring States period, Western-Zhou tombs included some lacquered objects, among them wooden vessels imitating the bronze or pottery ones like hu 壺, dou 豆, wan 碗, bei 杯, pan 盤, gui 簋, etc., small tables or desks (ji 几, zu 俎), objects of storage like cans or pots (lei 罍), round vessels (yi 彜), boxes (he 盒), tubes (tong 筒), or else. Lacquer was also used to decorate and strengthen leather armour or wooden shields.

Lacquering is mentioned in the chapter Zicai 梓材 of the Shangshu (tu dan huo 涂丹雘 "apply [in varnish] colours of red"), in various chapters of the Zhouli, the chapter Yugong, where lacquer is listed as a produce of the provinces of Yan, and Yu, and in some songs of the Shijing.

Wooden objects were first polished and then covered with raw lacquer mixed with ash (qihui 漆灰, nizi 膩子), in order to create a smooth surface on which the coloured finish (xiuqi 髹漆) was applied. Like on bronze and pottery vessels, lacquered vessels were decorated with geometrical patterns like spirals, clouds, or whirls. Two objects found in Liulihe close to Beijing were decorated with gold foil (jinbo 金箔), turquois stones, and disks of clam shell. An object unearthed in Honghong 洪洞, Shanxi, was a combination of bronze, wood, and lacquer (Zhang et al. 1987). The advance of handicraft techniques, and good organization allowed for the production of high-quality lacquerware.

In the field of architecture, earthenware tubes were used to dewater buildings. Among the objects found, there were also angled tubes (Zhou 2000: 871). A novelty created during the Western Zhou period were two types of tiles (wadang 瓦當), namely semi-tubular tiles (tongwa 筒瓦), and flat tiles (banwa 板瓦). The former were used to protect the ridges of the roofs—which were usually covered with straw or reed embedded in loam, and the latter were used to protect the roof coverage over larger parts. The flat tiles could be connected in mortise-and-tenon system. The semi-tubular tiles were fastened by nails which in turn were covered by earthenware decorations, the so-called tile nails (wading 瓦釘). The use of tiles was not widespread and only reserved to buildings of high status.